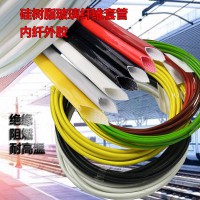

CY-GSZ硅树脂玻璃纤维套管,在紧密编织的玻纤套管外表上浸涂完整的硅树脂膜,经高温处理而成。具有良好的介电性以及较好的柔软性、阻燃性和耐温特点, 广泛应用于H&N级电机、家用电器、电热设备、特种灯具、电视及电子仪器的内部线束的集束、隔热、绝缘保护。

使用温度:-60℃~200℃

认证及标准:RoHS

颜色:白色,其它颜色可订做

产品参数:

|

项 目 Item |

硅树脂玻璃纤维套管 Silicone Glassfiber sleeving |

|

连续使用温度(℃) Temperature Endurance |

-10℃~+200℃ |

|

耐温性 Temperature Endurance |

200℃±2℃,168h≥1/2 原电压值 |

|

热老化 Aging Test |

260℃,6 小时,无裂纹 260℃,6h,No Cracking |

|

自熄时间(秒) Off-self Time (S) |

10 秒 10S |

|

水平燃烧 Horizontal Flame Test |

≤30 秒 ≤30S |

|

燃烧性 Flammability |

VW-1 |

|

体积电阻率(Ω.cm) Volume Resistivity |

1011 |

|

水解稳定性 Submerge Water Test |

不发粘,不变形,不软化 |

|

型号 Type |

测试条件 Testing Condition |

平均电压(伏) Average Voltage(v) |

个别值(伏) Individual Value(V) |

|

CY-GSZ-15 |

UL1441 |

1500 |

1000 |

|

CY-GSZ-25 |

UL1441 |

2500 |

1800 |

|

CY-GSZ -40 |

UL1441 |

4000 |

3000 |

|

CY-GSZ -70 |

UL1441 |

7000 |

5000 |

产品规格:

|

规 格 Size |

内径 I D ( mm ) |

最小壁厚(T) (mm) |

包装(米/盘) PackingLength (Meter/Roll) |

|||

|

1500V |

2500V |

4000V |

7000V |

|||

|

Φ 1.0 |

1.0 ±0 . 2 0 |

0.20+0.1 |

0.20+0.1 |

0.28+0.1 |

0.35+0.1 |

200 |

|

Φ 1.5 |

1.5 ±0 . 2 0 |

0.20+0.1 |

0.20+0.1 |

0.28+0.1 |

0.35+0.1 |

200 |

|

Φ 2.0 |

2. 5 ±0 . 2 0 |

0.22+0.1 |

0.22+0.1 |

0.30+0.1 |

0.38+0.1 |

100 |

|

Φ 2.5 |

3.0 ±0 . 2 0 |

0.22+0.1 |

0.22+0.1 |

0.30+0.1 |

0.38+0.1 |

100 |

|

Φ 3.0 |

3. 5 ±0 . 2 5 |

0.23+0.15 |

0.23+0.15 |

0.35+0.15 |

0.45+0.15 |

100 |

|

Φ 3.5 |

4.0 ±0 . 2 5 |

0.23+0.15 |

0.23+0.15 |

0.35+0.15 |

0.45+0.15 |

100 |

|

Φ 4.0 |

4. 5 ±0 . 2 5 |

0.25+0.15 |

0.25+0.15 |

0.38+0.15 |

0.45+0.15 |

100 |

|

Φ 4.5 |

5.0 ±0 . 2 5 |

0.28+0.15 |

0.30+0.15 |

0.40+0.15 |

0.48+0.15 |

100 |

|

Φ 5.0 |

5. 5 ±0 . 35 |

0.33+0.2 |

0.33+0.2 |

0.43+0.2 |

0.50+0.2 |

100 |

|

Φ 6.0 |

6. 5 ±0 .35 |

0.35+0.2 |

0.36+0.2 |

0.45+0.2 |

0.52+0.2 |

100 |

|

Φ 7.0 |

7. 5 ±0 .50 |

0.36+0.3 |

0.40+0.3 |

0.46+0.3 |

0.54+0.3 |

100 |

|

Φ 8.0 |

8. 5 ±0 .50 |

0.38+0.3 |

0.43+0.3 |

0.49+0.3 |

0.56+0.3 |

50 |

|

Φ 9.0 |

9. 5 ±0 .50 |

0.40+0.35 |

0.44+0.35 |

0.50+0.35 |

0.58+0.35 |

50 |

|

Φ 10.0 |

10 .5 ±0 .70 |

0.43+0.35 |

0.46+0.35 |

0.53+0.35 |

0.62+0.35 |

50 |

|

Φ 12.0 |

12 .5 ±0 .70 |

0.43+0.4 |

0.46+0.4 |

0.53+0.4 |

0.62+0.4 |

50 |

|

Φ 1 3 .0 |

1 3 .5 ±0 .70 |

0.43+0.4 |

0.46+0.4 |

0.53+0.4 |

0.62+0.4 |

50 |

|

Φ 1 4 .0 |

14±0.70 |

0.43+0.4 |

0.46+0.4 |

0.53+0.4 |

0.62+0.4 |

50 |

|

Φ 1 5 .0 |

1 5 .5 ±0 . 8 0 |

0.43+0.4 |

0.46+0.4 |

0.53+0.4 |

0.68+0.4 |

50 |

|

Φ 1 6 .0 |

1 6 .5 ±0 . 8 0 |

0.43+0. 5 |

0.46+0. 5 |

0. 6 3+0. 5 |

0. 7 +0. 5 |

50 |

|

Φ 1 8 .0 |

1 8 .5 ±0 . 8 0 |

0.43+0. 5 |

0.46+0. 5 |

0. 6 3+0. 5 |

0. 7 +0. 5 |

50 |

|

Φ 20.0 |

20.5 ±0 . 8 0 |

0.43+0. 5 |

0.46+0. 5 |

0. 6 3+0. 5 |

0. 7 +0. 5 |

50 |

|

Φ 22.0 |

22.5 ±0 . 8 0 |

0.43+0. 5 |

0.46+0. 5 |

0. 6 3+0. 5 |

0. 7 +0. 5 |

50 |

|

Φ 2 3 .0 |

23.5 ±0 . 8 0 |

0.43+0. 5 |

0.46+0. 5 |

0. 6 3+0. 5 |

0. 7 +0. 5 |

50 |

|

Φ 24.0 |

24.5 ±0 . 8 0 |

0.43+0. 5 |

0.46+0. 5 |

0. 6 3+0. 5 |

0. 7 +0. 5 |

50 |

|

Φ 25.0 |

25.5 ±0 . 8 0 |

0.43+0. 5 |

0.46+0. 5 |

0. 6 3+0. 5 |

0. 7 +0. 5 |

50 |

|

Φ 26.0 |

26.5 ±0 . 8 0 |

0.56+0. 6 |

0.56+0. 6 |

0.7 5 +0. 6 |

0.8+0. 6 |

50 |

|

Φ 27.0 |

2 7 .5 ± 1 .0 |

0.56+0. 6 |

0.56+0. 6 |

0.7 5 +0. 6 |

0.8+0. 6 |

50 |

|

Φ 28.0 |

2 8 .5 ± 1 .0 |

0.56+0. 6 |

0.56+0. 6 |

0.7 5 +0. 6 |

0.8+0. 6 |

50 |

|

Φ 30.0 |

30.5 ± 1 .0 |

0.56+0. 6 |

0.56+0. 6 |

0.7 5 +0. 6 |

0.8+0. 6 |

50 |

|

Φ 32.0 |

32.5 ± 1 .0 |

0.56+0. 6 |

0.56+0. 6 |

0.7 5 +0. 6 |

0.8+0. 6 |

25 |

|

Φ 35.0 |

35.5 ± 1 .0 |

0.56+0. 6 |

0.56+0. 6 |

0.7 5 +0. 6 |

0.8+0. 6 |

25 |

|

Φ 36.0 |

36.5 ± 1 .0 |

0.56+0. 6 |

0.56+0. 6 |

0.7 5 +0. 6 |

0.8+0. 6 |

25 |

|

Φ 45.0 |

45.5 ± 1 .0 |

0.56+0. 6 |

0.56+0. 6 |

0.7 5 +0. 6 |

0.8+0. 6 |

25 |